There are varying levels of complexity for machining tools. A magnet tool which is commonly used for holding down work pieces seems very archaic compared to an ultrasonic machining tool.

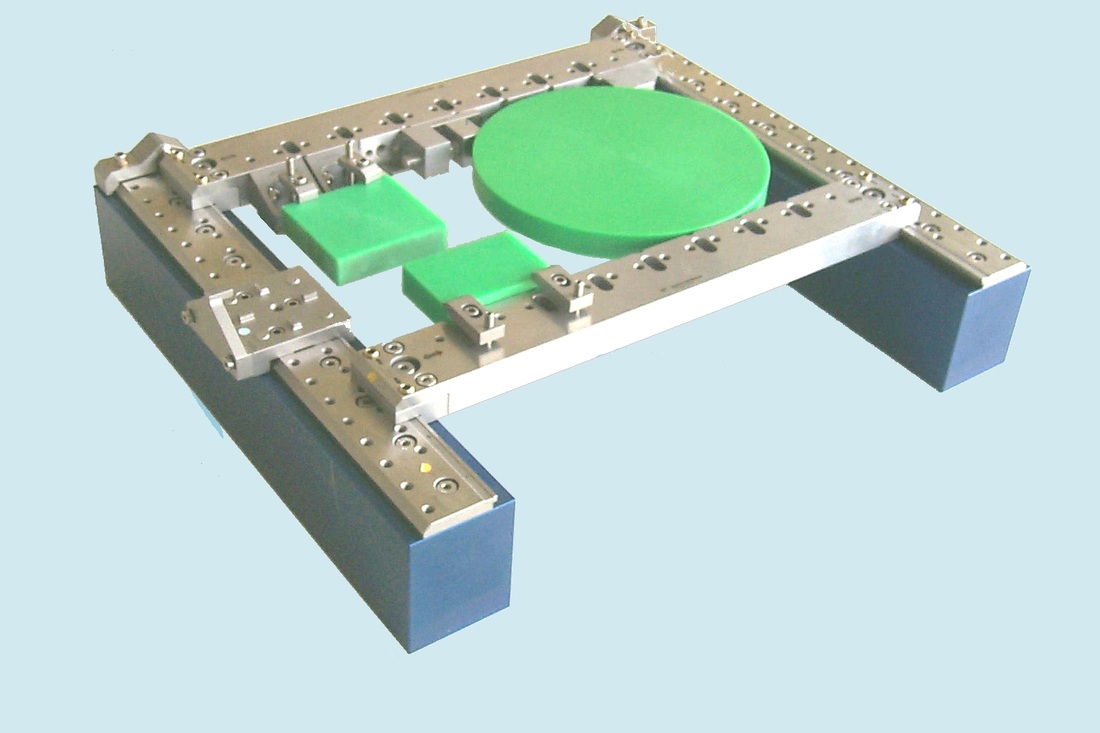

In ultrasonic machining, material is removed from the work piece with particles of abrasive that vibrate at a very high rate in a semi-liquid water mixture that circulates through a narrow space between a vibrating tool and the work piece. This non-traditional machining technique is mostly used for creating a cavity in material. The process is also known as ultrasonic impact grinding as the moving abrasive particles performs a grinding action on the work piece.

The vibrating tool which has the shaped of cavity that is to be produced oscillates up and down about 0.013 to 0.062 millimeter at 19,000 to 25,000 cycles per second. The oscillation causes the abrasive particles to vibrate against the surface of the work piece which then removes the material.

The oscillating tool made of a softer material than the work piece. Nickel and soft steels are the materials commonly used for the tool. As the tool pulsates, it pushes down on the abrasive particles on the surface of work piece. Under the impact of the abrasive particles, the surface of the work piece of the work piece abrades due to its brittleness while the softer tool material simply deforms slightly.

This method of machining is mostly used for cutting and shaping of hard and brittle materials that may either be conductors of electricity or insulators. It is also used for machining hardened steels, carbides and semiconductors.

There are several advantages to ultrasonic machining compared to other methods. It can be used for machining any hard material and creates a very good surface finish. There is also very little heat produced while other techniques create so much heat that a downtimes are required after several operations.

In ultrasonic machining, material is removed from the work piece with particles of abrasive that vibrate at a very high rate in a semi-liquid water mixture that circulates through a narrow space between a vibrating tool and the work piece. This non-traditional machining technique is mostly used for creating a cavity in material. The process is also known as ultrasonic impact grinding as the moving abrasive particles performs a grinding action on the work piece.

The vibrating tool which has the shaped of cavity that is to be produced oscillates up and down about 0.013 to 0.062 millimeter at 19,000 to 25,000 cycles per second. The oscillation causes the abrasive particles to vibrate against the surface of the work piece which then removes the material.

The oscillating tool made of a softer material than the work piece. Nickel and soft steels are the materials commonly used for the tool. As the tool pulsates, it pushes down on the abrasive particles on the surface of work piece. Under the impact of the abrasive particles, the surface of the work piece of the work piece abrades due to its brittleness while the softer tool material simply deforms slightly.

This method of machining is mostly used for cutting and shaping of hard and brittle materials that may either be conductors of electricity or insulators. It is also used for machining hardened steels, carbides and semiconductors.

There are several advantages to ultrasonic machining compared to other methods. It can be used for machining any hard material and creates a very good surface finish. There is also very little heat produced while other techniques create so much heat that a downtimes are required after several operations.

RSS Feed

RSS Feed